Epoxy industrial coating supplies are highly effective in harsh environments due to their exceptional durability, corrosion resistance, and ability to adhere strongly to various substrates. Here’s how they work and why they are so effective:

1. Mechanism of Action

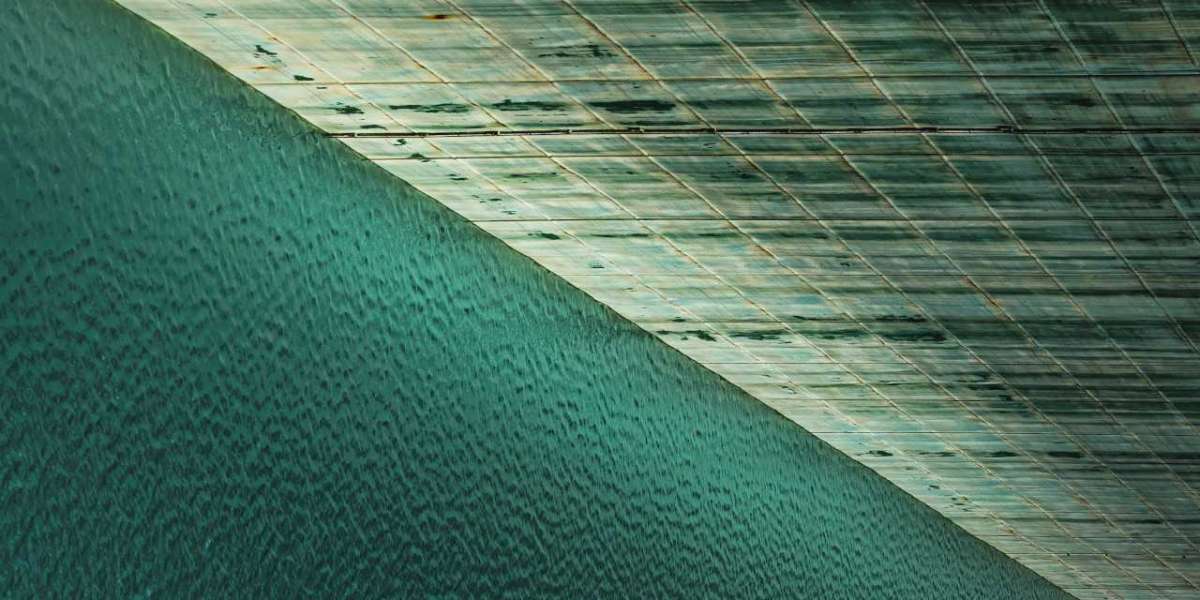

- Barrier Protection: Epoxy industrial coating supplies form an impermeable barrier over metal surfaces, preventing contact with water, air, and corrosive substances. This barrier stops the oxidation process, which is the primary cause of rust and corrosion.

- Adhesion and Durability: Once cured, epoxy industrial coating supplies create a hard, resilient surface that can withstand high levels of stress, abrasion, and impact. This durability ensures long-lasting protection in environments with frequent wear and tear.

- Chemical Resistance: Epoxy industrial coating supplies are highly resistant to chemicals, making them ideal for industrial settings where exposure to acids, alkalis, and solvents is common.

2. Applications in Harsh Environments

- Marine Environments: Epoxy industrial coating supplies are widely used on ships, offshore platforms, and other marine structures to protect against saltwater corrosion.

- Industrial Plants: In manufacturing and chemical plants, epoxy industrial coating supplies protect equipment from exposure to harsh chemicals and pollutants.

- High-Temperature Environments: Epoxy industrial coating supplies can withstand high temperatures, making them suitable for applications in power plants and refineries.

3. Enhanced Performance

- Modified Epoxy industrial coating supplies: Recent advancements include the use of graphene and metal oxides (such as ZnO and TiO₂) to enhance the anti-corrosion properties of epoxy industrial coating supplies. These modifications improve the interaction between the coating and the metal surface, providing better corrosion protection.

- Waterborne Epoxy industrial coating supplies: These eco-friendly industrial coating supplies offer excellent corrosion resistance, even in harsh oxygen environments. For example, a study showed that a graphene-modified waterborne epoxy coating maintained high impedance even after prolonged exposure to a 3.5% NaCl solution.

4. Practical Examples

- Offshore Oil Rigs: Epoxy industrial coating supplies are used to protect steel structures from the corrosive effects of seawater and harsh weather conditions.

- Mining Equipment: Epoxy industrial coating supplies protect against abrasive wear and chemical exposure in mining operations.

Conclusion

Epoxy industrial coating supplies are highly effective in harsh environments due to their ability to form a durable, impermeable barrier that protects metal surfaces from corrosion and wear. Their versatility and enhanced performance make them a preferred choice for industries facing extreme conditions.