Introduction

In the world of industrial manufacturing, precision, speed, and efficiency are everything. Whether it’s producing automotive components, electronic parts, or household goods, the process of shaping and cutting metal sheets forms the foundation of modern production. At the center of this process is the Press Tool—a highly specialized mechanical device designed to convert raw material into finished components with exact specifications.

A Press Tool is an essential element in industries that demand consistency and mass production. From automobile chassis to metal enclosures and consumer appliances, press tools are used everywhere. Understanding how they work, their types, and their role in production can help engineers, manufacturers, and designers optimize processes and reduce costs.

What Is a Press Tool?

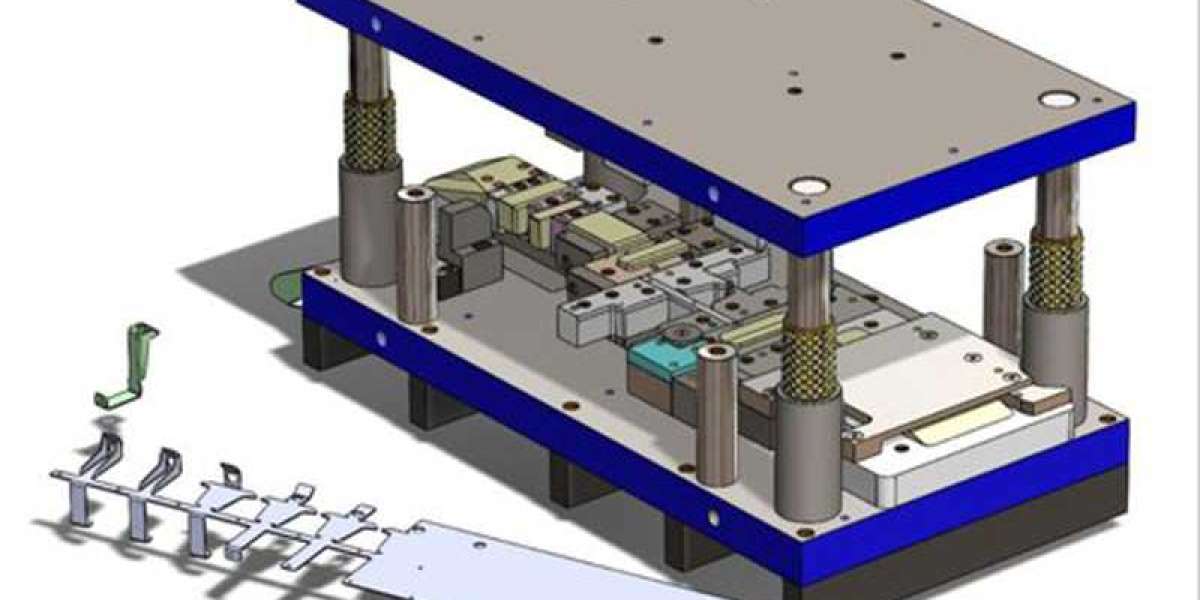

A Press Tool is a device fitted on a press machine to form, cut, or shape sheet metal or other materials into a specific form. It operates by applying mechanical or hydraulic pressure to the material between two halves of a die—one fixed (the lower half) and one movable (the upper half).

When pressure is applied, the material takes the shape of the die, producing components with high accuracy and repeatability. The process can be automatic or semi-automatic, depending on the design and purpose of the press tool.

Main Components of a Press Tool

A Press Tool consists of several key parts that work together to ensure accurate and efficient operation:

Punch – The male part that applies force to the sheet metal to shape or cut it.

Die – The female part that determines the final shape of the material.

Stripper Plate – Removes the sheet metal from the punch after each operation.

Guide Pillars and Bushes – Ensure precise alignment between punch and die.

Shank – Connects the upper portion of the press tool to the press machine.

Bolster Plate – A support plate where the die is mounted.

Each component must be designed and manufactured precisely to maintain performance and longevity, especially in high-volume production environments.

Types of Press Tools

Press tools come in different designs depending on the operation being performed. Some of the most common types include:

Blanking Tool

Used to cut out a flat piece of sheet metal, known as a blank.

Example: Cutting discs for car wheels or washers.

Piercing Tool

Creates holes or openings in the sheet metal without removing the outer part.

Common in making electrical panels or enclosures.

Bending Tool

Used to bend the sheet metal at specific angles without breaking it.

Ideal for making brackets or metal frames.

Forming Tool

Shapes the metal into curved or complex forms.

Used in producing automotive body parts and appliance casings.

Drawing Tool

Draws or stretches the material into hollow shapes such as cups or cylinders.

Common in making cans, containers, and kitchen utensils.

Combination Tool

Performs multiple operations like cutting and bending in a single stroke.

Useful for reducing time and increasing productivity.

Progressive Tool

A high-speed tool used in automatic presses that performs multiple operations sequentially as the sheet progresses through the die.

Common in large-scale manufacturing for automotive or electrical parts.

Working Principle of a Press Tool

The operation of a Press Tool is based on the simple principle of applying force through a press machine. Here’s a step-by-step overview of the process:

The sheet metal (workpiece) is placed between the punch and the die.

The punch is subjected to downward force by the press machine.

The material deforms or gets cut, taking the shape of the die cavity.

The stripper plate removes the finished part from the punch.

The process repeats for each cycle, ensuring consistent output.

Depending on the type of press—mechanical, hydraulic, or pneumatic—the speed and force can vary significantly. Mechanical presses are faster, while hydraulic presses offer greater control and power.

Applications of Press Tools

Press Tools play a critical role in various industries, including:

Automotive: Manufacturing body panels, brackets, and engine components.

Electronics: Producing metal housings, connectors, and heat sinks.

Appliances: Creating panels for washing machines, ovens, and refrigerators.

Construction: Producing metal fittings, frames, and structural supports.

Essentially, any product that involves metal parts likely relies on a Press Tool during production.

Advantages of Using a Press Tool

High Precision and Consistency

Every piece produced is identical in shape and size, which is critical for mass production.

High Production Rate

Press tools can produce thousands of parts per hour, improving efficiency.

Reduced Labor Costs

Automation minimizes manual handling and speeds up the production cycle.

Material Utilization

Modern press tools are designed to reduce material waste during cutting and forming.

With proper maintenance, a well-designed Press Tool can last for years, even under continuous use.

Maintenance and Care for Press Tools

To ensure long service life and consistent output, regular maintenance of Press Tools is essential. Here are some key practices:

Lubrication: Keeps moving parts smooth and reduces wear.

Cleaning: Removes debris and metal scraps that can damage the die.

Inspection: Check for wear, cracks, or misalignment.

Sharpening: Maintain cutting edges to ensure clean operations.

Storage: Keep tools in a dry, temperature-controlled environment to prevent rust.

Regular upkeep minimizes downtime, extends tool life, and maintains production quality.

Modern Innovations in Press Tool Design

With advancements in technology, Press Tools have evolved significantly. Today’s designs integrate:

CNC machining for ultra-precise die manufacturing.

CAD/CAM software for simulation and stress analysis.

Carbide or coated steels for longer wear resistance.

Automation and robotics for improved safety and efficiency.

These innovations reduce production errors, shorten lead times, and allow manufacturers to create more complex and high-quality components.

Conclusion

In today’s competitive manufacturing environment, the Press Tool stands as a cornerstone of productivity and precision. Its ability to produce complex shapes with speed and accuracy makes it indispensable across industries. From the simplest washer to advanced automotive parts, press tools make mass production possible, efficient, and economical.

see more our website:visit here