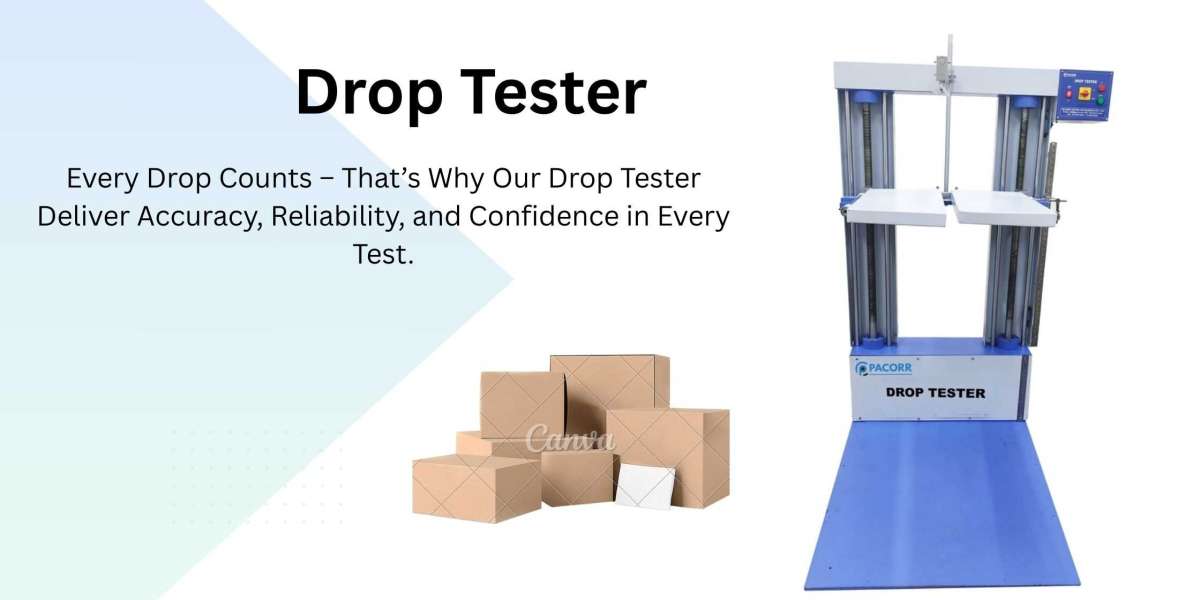

What is a Drop Tester?

A Drop Tester is a device used to simulate the impact forces that packages experience during transportation. It is designed to drop a package from a specified height onto a surface, replicating the potential damage caused by mishandling, dropping, or rough handling during transit. The Drop Tester provides valuable data that helps manufacturers and suppliers to assess the durability of their packaging materials and products.

Why is Drop Testing Crucial for Packaging?

Packaging is essential for protecting products from external damage. Inconsistent handling, falling, or even slight impacts can lead to product failure, loss of integrity, and even customer dissatisfaction. This is where the Drop Tester plays a critical role. By testing packaging's ability to withstand drops, manufacturers can ensure that their products will remain intact throughout the distribution process.

Drop testing also helps companies meet international packaging standards and regulations. Different industries, such as electronics, food, pharmaceutical, and automotive, require specific packaging strength criteria. A Drop Tester ensures that the packaging adheres to these standards, preventing potential product damage and costly returns.

How Does a Drop Tester Work?

A Drop Tester works by lifting a package to a predetermined height and releasing it to fall freely onto a specified surface. The tester simulates different drop angles, such as flat drops, edge drops, or corner drops, to see how the packaging reacts under various conditions. The drop height, which can be adjusted, and the surface type (like concrete, wood, or steel) are customizable based on industry requirements.

The Drop Tester features a controlled setup that ensures consistency in every test. After the drop, the package is inspected to check for any visible damages. Some advanced models are equipped with data recording features to track impact forces, drop height, and other relevant parameters.

Types of Drop Testers

There are several types of Drop Testers, each designed for specific applications and testing standards. The most common types include:

Vertical Drop Testers: These testers allow packages to be dropped from different heights along a vertical axis. Ideal for products that require testing from a height to simulate the shipping process.

Rotary Drop Testers: These machines rotate the package during the drop to simulate more complex handling situations where packages might tumble or spin during transport.

Inclined Drop Testers: This type of tester is used when packages need to be dropped at an angle to replicate the real-world scenario of uneven transportation surfaces.

Each Drop Tester can be customized based on the product’s requirements, ensuring the testing process reflects the actual conditions a product might face.

Benefits of Using a Drop Tester

Using a Drop Tester provides numerous benefits that can significantly improve the quality of packaging. Some key benefits include:

Ensures Product Protection: Drop testing helps identify weak points in packaging design, such as insufficient padding, fragile edges, or weak seals, allowing manufacturers to make necessary adjustments before products reach the market.

Improves Customer Satisfaction: By ensuring that packaging meets the required standards, a Drop Tester reduces the chances of customer complaints due to damaged products, enhancing brand reputation.

Cost Efficiency: Testing the packaging in a controlled environment allows companies to optimize their packaging materials and reduce unnecessary costs related to damage or returns from defective packaging.

Compliance with Industry Standards: A Drop Tester ensures that the packaging complies with various international standards, including ASTM, ISO, and ISTA. Meeting these standards is critical for global product distribution.

Prevents Product Damage: By simulating different drop scenarios, the Drop Testing helps in understanding how the product will behave under various shipping conditions, ultimately preventing costly product damage.

Drop Tester Standards and Certifications

To ensure accuracy and reliability, it is essential to adhere to international standards when conducting drop tests. Some of the commonly referenced standards include:

ASTM D5276: This standard covers the procedures for drop testing of packaged products.

ISTA 1A/3A: These standards specify test procedures for various types of product packaging to evaluate their ability to withstand impacts.

ISO 2233: This standard provides guidelines for simulating environmental conditions during transportation, including vibration and impact testing.

How to Choose the Right Drop Tester

When selecting a Drop Tester for your packaging needs, several factors should be considered:

Test Height: Choose a tester that can simulate the necessary height based on your product’s shipping conditions.

Type of Products: Consider the type of products you are testing. Fragile items may require more detailed testing, such as rotary or inclined tests.

Testing Standards: Ensure the tester adheres to international standards relevant to your industry.

Data Recording: Advanced models that provide detailed data can help in analyzing the test results comprehensively.

Ease of Use: A user-friendly interface will ensure smooth operation and quicker testing cycles.

Conclusion: Investing in a Drop Tester

In the world of packaging, the safety and durability of a product during transit cannot be overstated. A Drop Tester is an indispensable tool for any company that deals with shipping products. By simulating real-world handling and transportation scenarios, the Drop Tester Price helps ensure that packaging meets safety standards, reduces product damage, and improves customer satisfaction.

When selecting a Drop Tester, it’s essential to choose one that suits your product’s needs, adheres to industry standards, and provides reliable and accurate testing. With the right Drop Tester, manufacturers can ensure that their products reach consumers in perfect condition, ultimately safeguarding their reputation and bottom line.