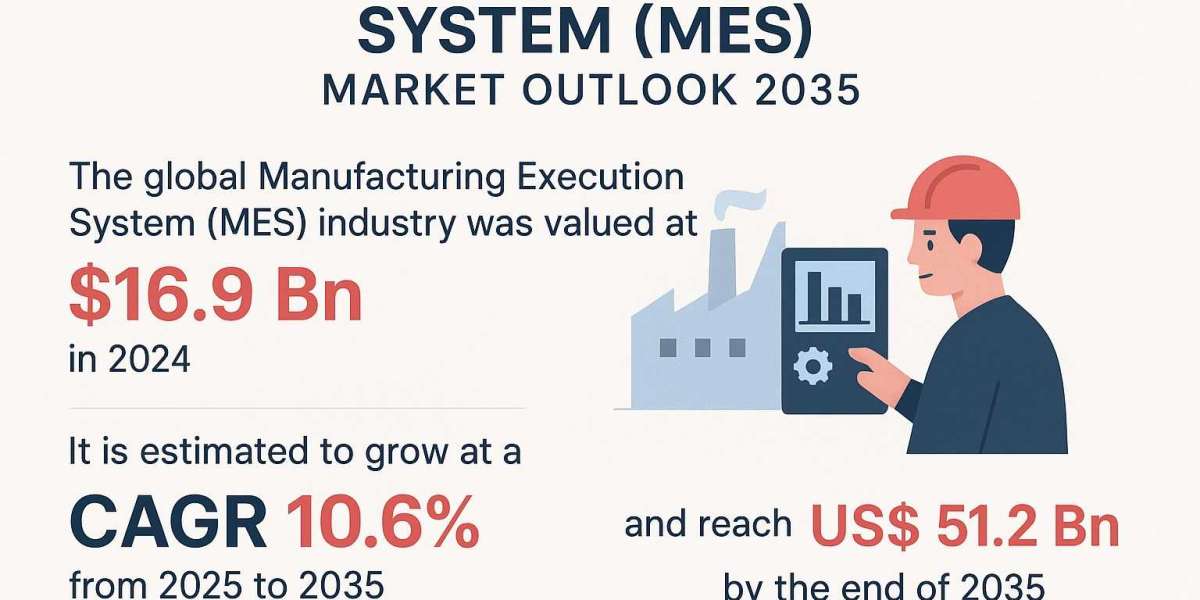

The global Manufacturing Execution System (MES) market is witnessing an unprecedented surge, fueled by the global push toward smart manufacturing, Industry 4.0 integration, and real-time production intelligence. Valued at US$ 16.9 billion in 2024, the MES market is expected to grow at a robust CAGR of 10.6% between 2025 and 2035, ultimately reaching a market valuation of US$ 51.2 billion by 2035.

As industries across sectors—automotive, pharmaceuticals, electronics, and consumer goods—embrace digital transformation, MES platforms are becoming the digital backbone of industrial operations, bridging the gap between enterprise-level planning and shop floor execution.

The Evolution of MES in the Digital Manufacturing Era

In an age where manufacturing competitiveness depends on efficiency, traceability, and flexibility, MES systems have emerged as indispensable. They offer real-time visibility, process management, and operational analytics that empower manufacturers to make informed, data-driven decisions.

MES acts as a connective layer between enterprise resource planning (ERP) systems and operational technologies (OT) on the shop floor. It ensures synchronization between planning and execution, allowing manufacturers to monitor production, manage workflows, and ensure compliance with regulatory and quality standards.

The rise of Industry 4.0 and smart factory initiatives has transformed MES from a traditional production control system into a central digital intelligence hub. Countries such as the U.S., China, India, and members of the European Union are actively investing in industrial digitalization programs, driving further MES adoption.

Analysts’ Viewpoint: MES as the Heart of Next-Gen Manufacturing

Industry analysts highlight that MES growth is no longer confined to large-scale industries. Cloud-based MES solutions, along with integration of IoT, AI, and advanced analytics, are making these systems accessible to small and medium enterprises (SMEs).

As manufacturers seek to streamline workflows, enhance traceability, and ensure regulatory compliance, MES solutions are evolving into comprehensive platforms for predictive maintenance, real-time quality control, and performance optimization.

Smart factories across the globe are receiving significant investments as the focus shifts toward data-driven, flexible production systems. The trend toward cloud deployment models not only reduces upfront costs but also improves scalability and interoperability—two critical factors driving MES growth across diverse industry verticals.

Market Drivers

1. Industry 4.0 and Smart Manufacturing: The Core Growth Engine

The global transition toward Industry 4.0 is fundamentally transforming manufacturing landscapes. Automation, robotics, artificial intelligence (AI), and the Internet of Things (IoT) have created complex digital ecosystems that require seamless coordination—precisely what MES delivers.

MES enables real-time data visibility, process control, and intelligent integration across manufacturing operations, ensuring that every component of production—from supply chain to product delivery—is synchronized for efficiency and quality.

Governments and organizations worldwide are backing this transformation. For example, in February 2025, Maryland’s Manufacturing 4.0 initiative received US$ 5 million to support manufacturers adopting Industry 4.0 technologies, including MES systems.

2. Government Initiatives and Policy Support

Public sector initiatives are becoming crucial accelerators of MES adoption. Programs such as “Made in China 2025,” “Make in India,” and the EU’s “Industry 5.0” vision are pushing industries toward connected, automated, and sustainable manufacturing.

Similarly, the U.S. Department of Energy (DOE) has introduced grants exceeding US$ 22 million to help small- and medium-sized manufacturers implement smart manufacturing tools, including MES platforms, advanced sensors, and analytics-driven process control systems.

These initiatives not only fund technology adoption but also establish regulatory frameworks that incentivize digital modernization, positioning MES as a strategic enabler for competitiveness, sustainability, and innovation.

Technology Trends Transforming the MES Landscape

The MES market is rapidly evolving, with several emerging technologies redefining its capabilities:

Cloud-based MES Platforms: Offering scalability, cost-efficiency, and remote accessibility.

Artificial Intelligence (AI) and Machine Learning (ML): Enabling predictive maintenance, quality assurance, and intelligent production scheduling.

Digital Twins: Creating virtual replicas of physical manufacturing systems for performance optimization and scenario testing.

Edge Computing: Bringing real-time data processing closer to production sources for faster insights and response times.

Blockchain Integration: Strengthening traceability, transparency, and cybersecurity across manufacturing networks.

These technologies collectively drive end-to-end digital visibility, making MES an essential pillar in building the connected, resilient factories of the future.

Market Segmentation Insights

By Offering: Software Dominates the Market

The software segment holds a commanding 61.2% share of the MES market. Software solutions drive key functions such as production scheduling, quality management, and traceability, helping manufacturers achieve operational excellence and compliance with industry standards.

The rapid evolution of AI-integrated and IoT-enabled MES platforms has further solidified software’s dominance, while service segments—such as system integration, maintenance, and advisory—act as complementary growth enablers.

By Deployment: The Shift to Cloud

Manufacturers are increasingly opting for cloud-based MES over on-premise models. Hybrid and private cloud deployments are gaining traction for their balance of data security and scalability. This shift is especially prevalent among SMEs seeking affordable, flexible digital transformation paths.

By End User: Diverse Industrial Adoption

While automotive, electronics, and pharmaceuticals remain key adopters, MES deployment is expanding across food beverages, energy, oil gas, and chemicals industries. In these sectors, MES helps achieve enhanced traceability, process efficiency, and regulatory compliance—critical in highly regulated and quality-sensitive environments.

Regional Analysis

North America: Leading the Global MES Revolution

North America leads the global MES market, commanding a 38.6% market share. The region benefits from a mature industrial ecosystem, strong technology infrastructure, and early adoption of automation and digital manufacturing technologies.

The U.S., in particular, remains a hub of MES innovation. A notable example includes the SMART USA Institute, a US$ 285 million initiative launched by the U.S. Department of Commerce and Semiconductor Research Corporation. The program promotes digital twins and AI-driven automation to advance semiconductor manufacturing efficiency.

The region’s strong focus on sustainability, quality assurance, and operational excellence ensures that North America will continue to dominate the MES market throughout the forecast period.

Competitive Landscape

The MES market features an intense competitive environment characterized by continuous innovation and strategic partnerships. Major players include:

Siemens AG

Dassault Systèmes

SAP SE

Rockwell Automation Inc.

Honeywell International Inc.

ABB Ltd.

Emerson Electric Co.

GE Vernova

Oracle Corporation

Schneider Electric SE

These companies are expanding their portfolios through AI integration, cloud-based solutions, and sector-specific MES offerings.

Recent developments include:

Dassault Systèmes (Feb 2024): Partnered with Groupe Clarins to use its 3DEXPERIENCE platform for streamlined manufacturing and capacity expansion.

Emerson Electric (Apr 2024): Launched DeltaV Workflow Management, an MES software for life sciences companies to enhance process scalability and compliance.

Conclusion

The Manufacturing Execution System (MES) market is poised to become a cornerstone of global industrial digitalization by 2035. With its valuation expected to triple to over US$ 51.2 billion, MES adoption will continue to accelerate across regions and sectors, driven by the convergence of AI, IoT, cloud computing, and government-backed smart manufacturing initiatives.

As MES evolves into a central hub for real-time decision-making, predictive insights, and sustainable production, manufacturers that embrace these systems early will gain a decisive edge in efficiency, quality, and agility—defining the next generation of smart, data-driven global manufacturing.